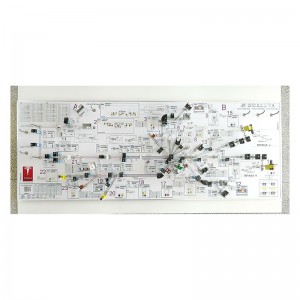

Automobile Wiring Harness Card Pin Testing Platform

Card pin wiring harness testing platforms have many advantages.

Firstly, they significantly improve the efficiency and accuracy of testing. With advanced testing equipment and automated processes, the speed and accuracy of testing are greatly improved.

Secondly, they help to reduce the defects and risks in the production process. Any defects or problems detected by the testing platform can be promptly repaired or resolved, reducing the likelihood of product failures or safety risks.

Thirdly, they help to reduce the overall cost of production. By quickly identifying and resolving problems, the testing platform can prevent costly mistakes and ensure that only high-quality wiring harnesses are produced.

Finally, card pin wiring harness testing platforms can be customized to meet specific production needs. Manufacturers can choose from a range of fixtures and accessories to create a platform that is tailored to their requirements. In recent years, with the development of new technologies such as artificial intelligence and the Internet of Things (IoT), card pin wiring harness testing platforms have become even more advanced and sophisticated. For example, some platforms now use machine learning algorithms to analyze data and identify patterns that can help improve the accuracy and efficiency of testing. Others can be integrated with IoT sensors and cloud-based systems to enable real-time monitoring and remote management of production processes.

In conclusion, card pin wiring harness testing platforms are essential tools for manufacturers of a wide range of products that use wiring harnesses. By improving the efficiency, accuracy, and quality of production processes, these platforms help to ensure that only the highest-quality products reach the market, while also reducing the overall cost of production.

First innovated by Yongjie company, flat material barrel is applied to the Card pin Mounting Testing platform. Advantages of the new innovated testing platform are:

1. The flat surface enables the operators to place the wiring harness smoothly without any obstacle. The flat surface also provide better view during operation.

2. The depth of material barrels is adjustable according to different length of cable clips. The flat surface concept reduces working intensity and improves working efficiency by enable the operators to access material without lifting their arms.